bulk wool cutting length customization

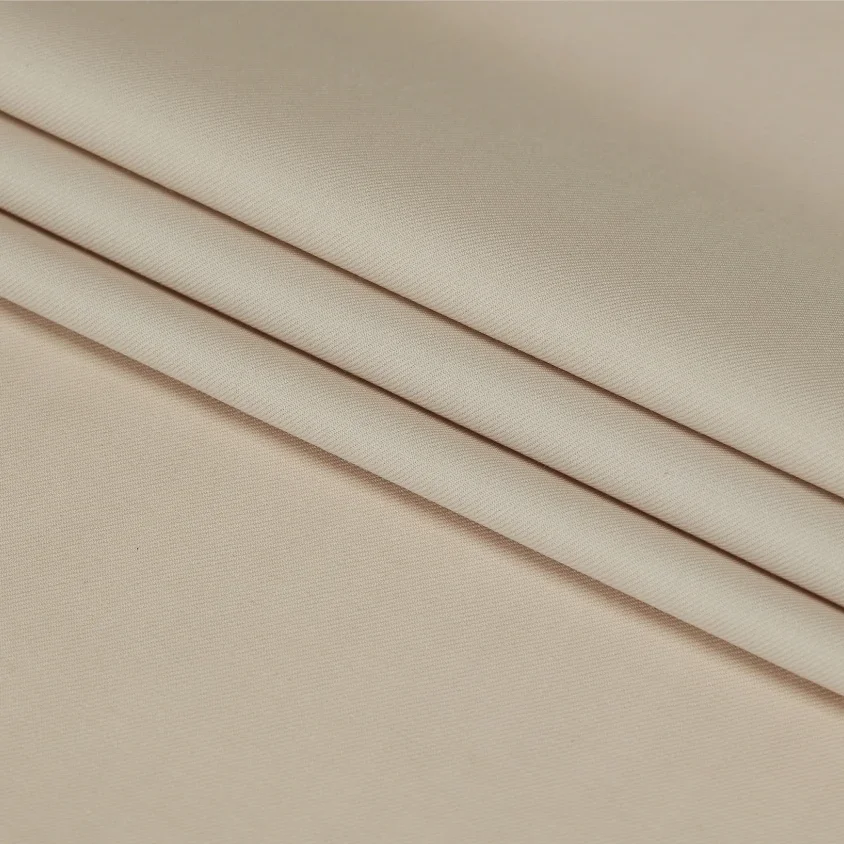

Bulk wool cutting length customization represents a sophisticated manufacturing process that allows for precise control over wool fiber dimensions in large-scale production. This advanced system enables manufacturers to achieve consistent fiber lengths according to specific requirements, ensuring optimal quality for various applications. The technology incorporates state-of-the-art cutting mechanisms with adjustable settings, allowing for lengths ranging from ultra-short fibers for specialized textiles to longer staples for traditional wool products. The process utilizes automated feeding systems, precision cutting blades, and computer-controlled operations to maintain uniformity across large batches. This customization capability is essential for producing wool products that meet exact specifications for different end uses, from fine merino clothing to industrial applications. The system features advanced monitoring equipment that ensures consistent cutting accuracy, while integrated quality control measures continuously verify the output meets predetermined standards. Additionally, the technology includes waste reduction mechanisms and fiber recovery systems, maximizing material utilization and operational efficiency. This comprehensive approach to wool length customization serves various industries, including fashion, upholstery, technical textiles, and specialized manufacturing sectors.