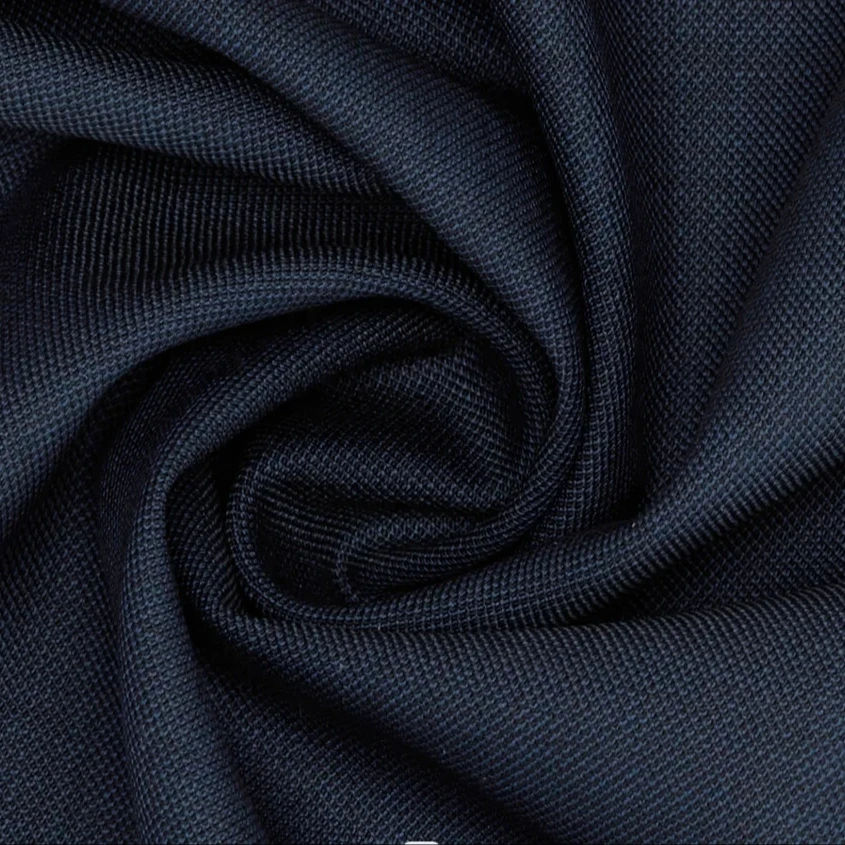

custom worsted wool fabric supplier

A custom worsted wool fabric supplier represents a specialized textile manufacturing entity that focuses on producing high-quality worsted wool materials tailored to specific customer requirements. These suppliers utilize advanced spinning and weaving technologies to transform fine wool fibers into smooth, durable, and sophisticated fabrics. The production process involves careful selection of raw wool, followed by thorough cleaning, combing, and spinning to create yarns with parallel fibers. This meticulous process results in fabrics that exhibit superior draping qualities, exceptional durability, and remarkable resistance to wrinkles. Modern suppliers employ state-of-the-art machinery and quality control systems to ensure consistent fabric characteristics, including weight, texture, and finish. They offer customization options in terms of weight (ranging from lightweight 7oz to heavyweight 16oz), patterns, colors, and finishing treatments. These suppliers typically serve various sectors, including high-end fashion houses, bespoke tailoring establishments, and luxury garment manufacturers. Their expertise extends to developing specialized treatments for enhanced performance characteristics such as water resistance, stretch properties, and temperature regulation.