group order for uniform wool fabrics

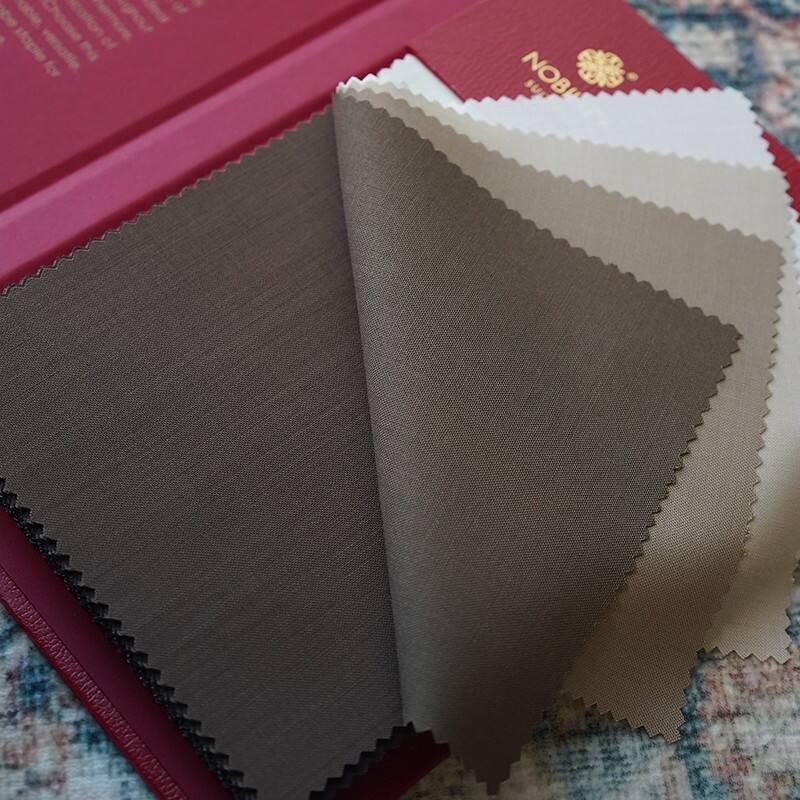

Group order for uniform wool fabrics represents a strategic approach to textile procurement that combines efficiency, cost-effectiveness, and quality assurance. This procurement method enables organizations to purchase high-quality wool fabrics in bulk quantities, specifically designed for uniform applications. The process involves coordinating multiple buyers to achieve economies of scale, resulting in substantial cost savings while maintaining consistent quality standards. These wool fabrics are engineered with advanced manufacturing techniques, ensuring durability, color fastness, and comfort for end-users. The fabrics undergo rigorous quality control measures, including tests for shrinkage resistance, colorfastness, and wear resistance. Modern production methods incorporate innovative finishing treatments that enhance the fabric's performance characteristics, such as wrinkle resistance, moisture-wicking properties, and enhanced breathability. The group ordering system also facilitates customization options, allowing organizations to specify particular weaves, weights, and finishes that meet their exact requirements. This approach is particularly beneficial for educational institutions, corporate organizations, and uniformed services that require large quantities of consistent, high-quality wool fabrics for their uniform programs.