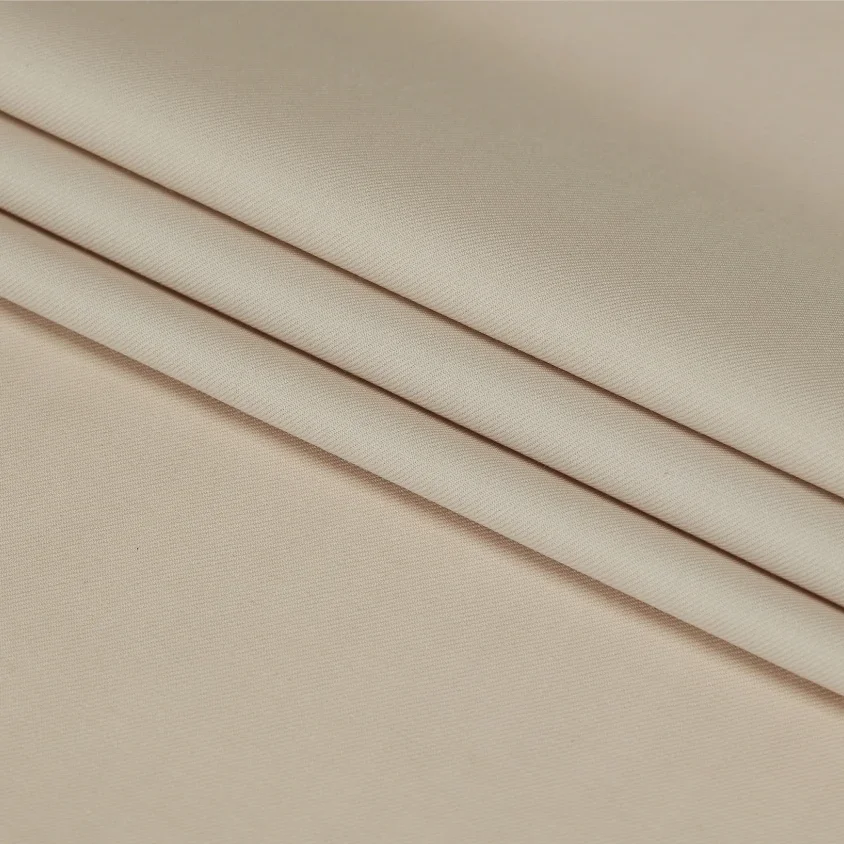

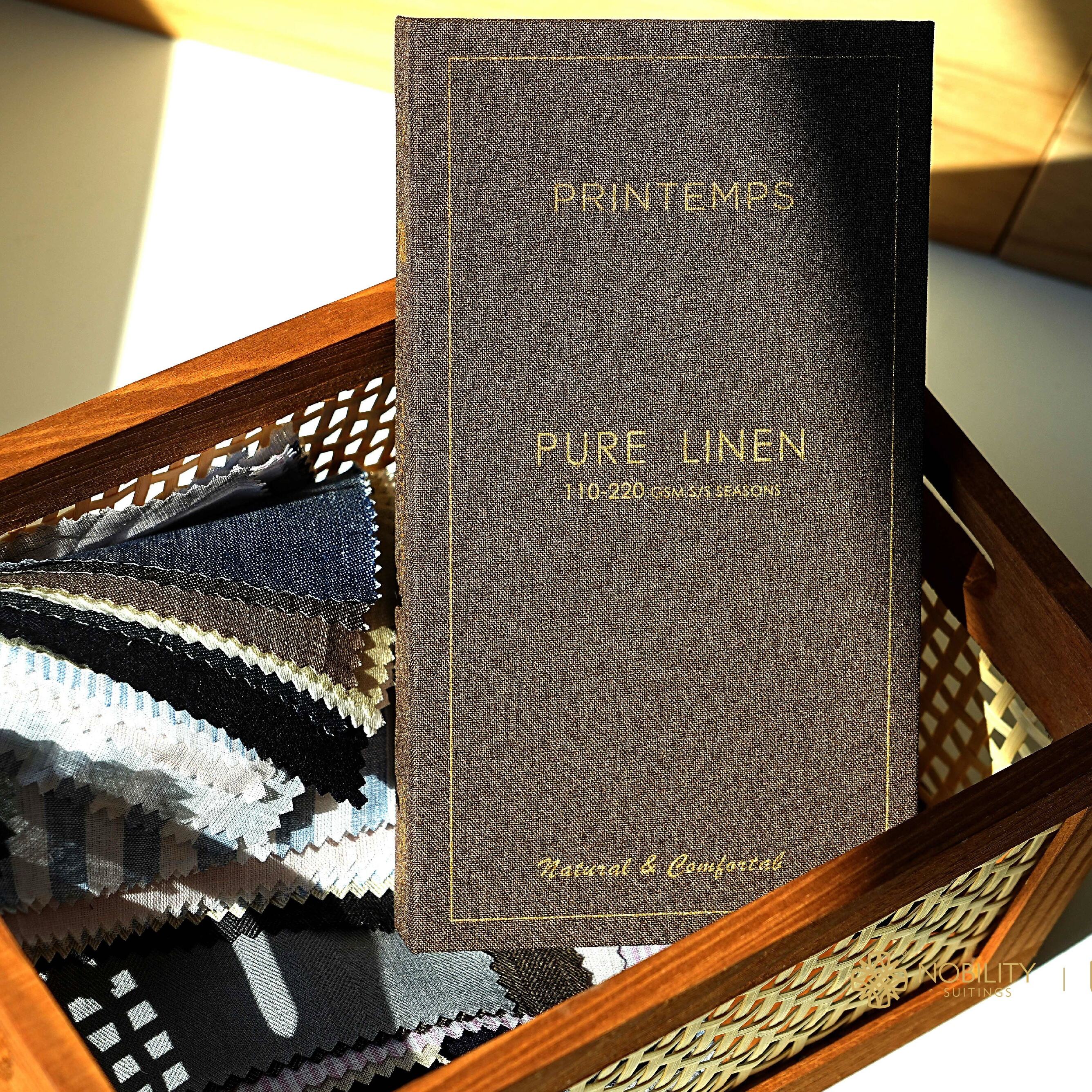

pure linen fabric manufacturer

A pure linen fabric manufacturer represents a specialized industrial entity dedicated to producing high-quality linen textiles through advanced manufacturing processes. These facilities combine traditional craftsmanship with modern technology to transform raw flax fibers into premium linen fabrics. The manufacturing process involves multiple sophisticated stages, including fiber preparation, spinning, weaving, and finishing treatments. State-of-the-art machinery enables precise control over fabric weight, texture, and durability while maintaining the natural characteristics of linen. These manufacturers typically operate large-scale facilities equipped with automated looms, quality control systems, and specialized finishing equipment. Their operations encompass everything from sourcing premium flax fibers to implementing eco-friendly production methods that minimize environmental impact. The facilities often feature advanced climate-controlled environments to ensure optimal processing conditions, along with research and development departments focused on innovative weaving techniques and sustainable practices. The manufacturer's expertise extends to creating various linen weights and styles, from lightweight summer fabrics to heavier upholstery-grade materials, serving diverse market segments including fashion, home textiles, and industrial applications.