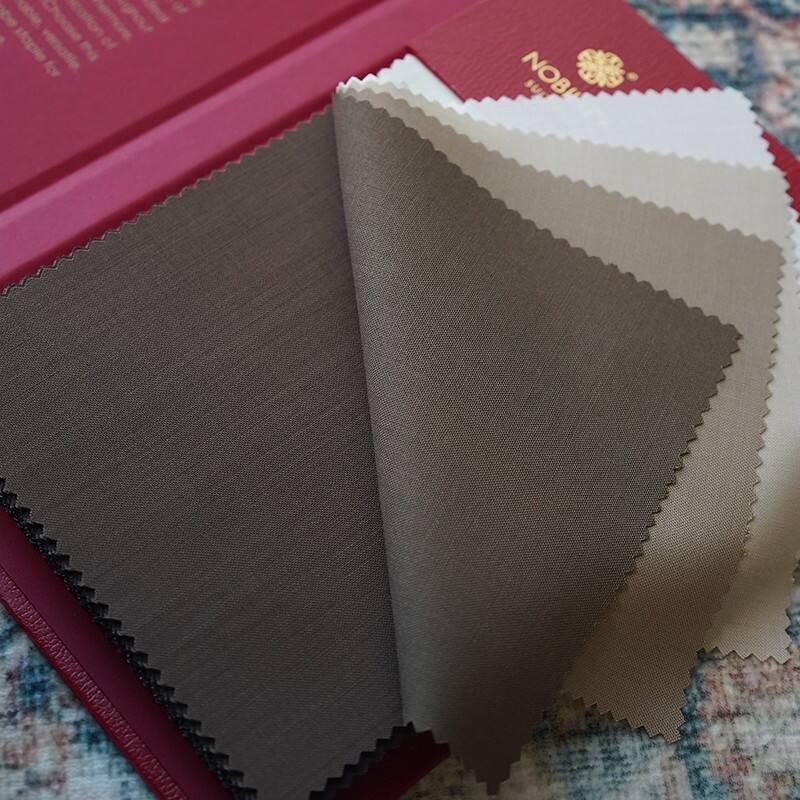

wool blend fabric manufacturer own factory

A wool blend fabric manufacturer own factory represents a state-of-the-art facility dedicated to producing high-quality textile materials that combine wool with other fibers for enhanced performance and versatility. These modern manufacturing facilities integrate advanced machinery and quality control systems to ensure consistent product quality. The factory typically houses comprehensive production lines that handle everything from fiber blending and spinning to weaving and finishing processes. With automated systems and precision equipment, these facilities can produce various wool blend fabrics with different weights, textures, and compositions to meet diverse market demands. The factory's in-house testing laboratories conduct rigorous quality assessments, checking for durability, colorfastness, and compliance with international standards. Climate-controlled environments maintain optimal conditions for wool processing, while sophisticated ventilation systems ensure proper air quality. The facility's vertical integration allows for better control over the entire production process, from raw material selection to final product inspection. Advanced dyeing and finishing departments utilize eco-friendly technologies to achieve desired colors and special treatments while minimizing environmental impact. The factory's research and development center continuously works on innovative blend compositions and manufacturing techniques to create fabrics with enhanced properties such as wrinkle resistance, moisture-wicking, and thermal regulation.