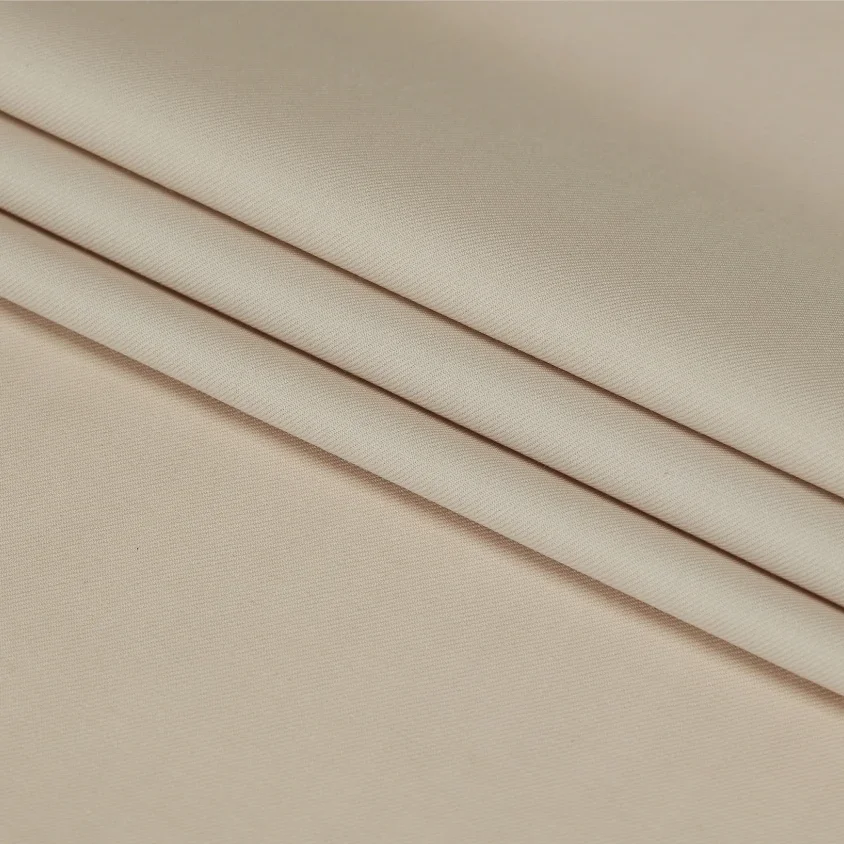

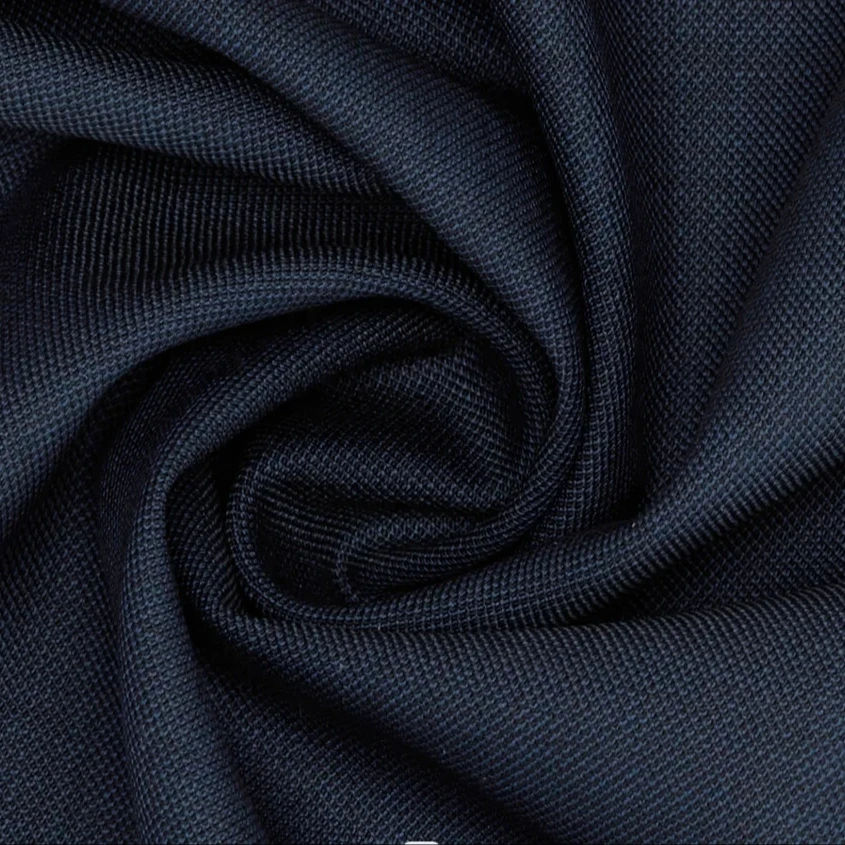

wool blend suiting fabric factory

A wool blend suiting fabric factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality textile materials that combine wool with other fibers for superior performance and cost-effectiveness. These facilities employ advanced machinery and precise production processes to create fabrics that maintain the luxurious feel and durability of wool while incorporating the benefits of synthetic or natural fiber blends. The factory's operations encompass multiple stages, from raw material selection and quality control to spinning, weaving, and finishing processes. Modern wool blend factories utilize computer-controlled equipment to ensure consistent quality and precise fiber ratios in their products. The facility's climate-controlled environment maintains optimal conditions for fabric production, while sophisticated testing laboratories verify the quality and performance characteristics of finished materials. These factories typically produce a wide range of fabric weights and patterns, catering to various market segments from business suits to casual wear. The integration of sustainable practices and eco-friendly technologies has become increasingly important, with many facilities implementing water recycling systems and energy-efficient machinery. The factory's expertise extends to developing custom blends that meet specific customer requirements for durability, comfort, and appearance, making them essential partners in the modern fashion and textile industry.