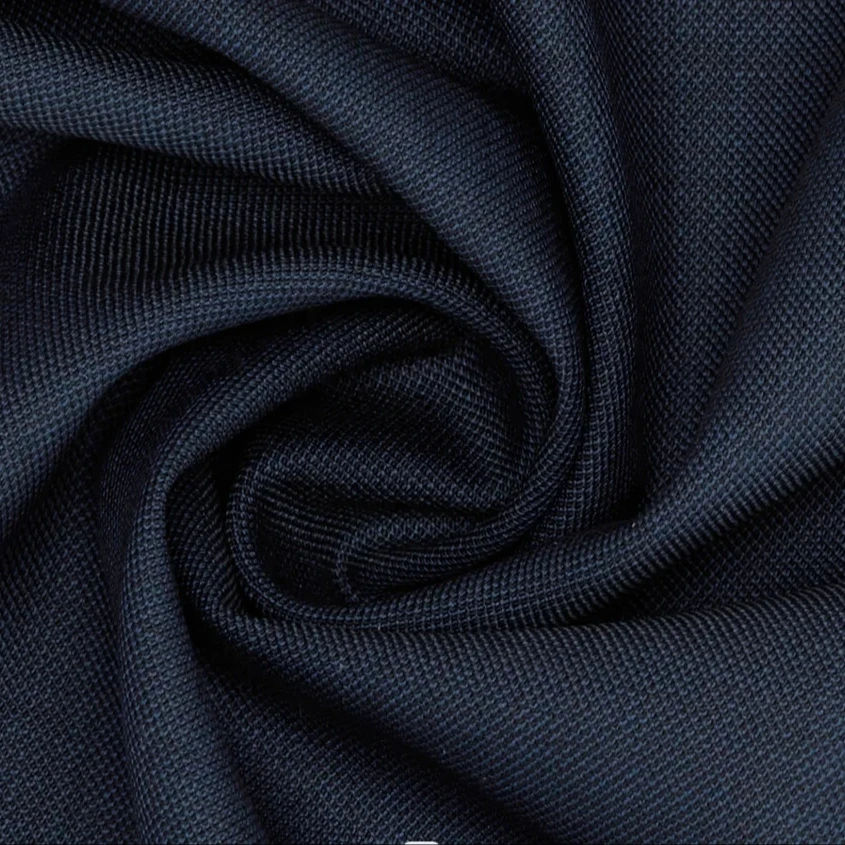

wool suits fabric factory

A wool suits fabric factory represents a sophisticated manufacturing facility dedicated to producing high-quality textile materials specifically designed for formal wear and business attire. These facilities combine traditional craftsmanship with modern manufacturing technologies to create premium wool fabrics that meet the exacting standards of contemporary fashion. The factory utilizes state-of-the-art machinery for processes including wool sorting, cleaning, carding, spinning, weaving, and finishing. Quality control systems monitor every stage of production, ensuring consistency in texture, weight, and appearance. Advanced dyeing facilities enable precise color matching and treatment processes that enhance the fabric's durability and appearance. The factory incorporates specialized testing laboratories where fabrics undergo rigorous examinations for strength, durability, and comfort metrics. Environmental control systems maintain optimal temperature and humidity levels throughout the production areas, crucial for wool processing. Modern inventory management systems track raw materials and finished products, while automated cutting and inspection equipment ensures precise fabric dimensioning and quality standards. The facility also features dedicated research and development departments focused on fabric innovation and sustainable production methods.