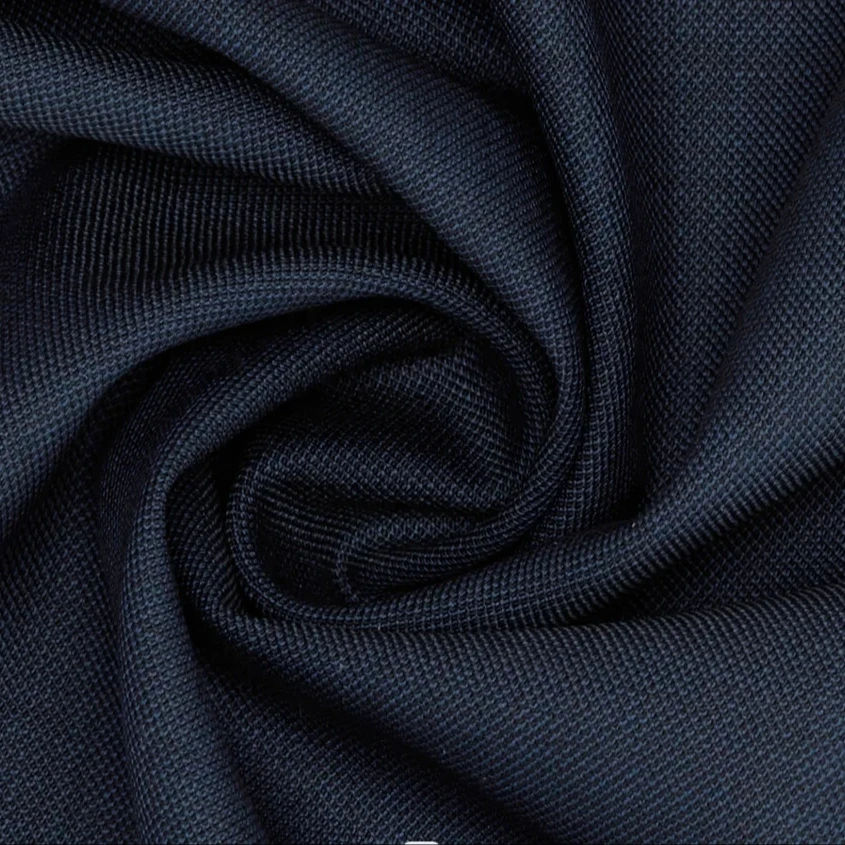

worsted wool suiting fabric factory

A worsted wool suiting fabric factory represents a cutting-edge manufacturing facility dedicated to producing premium quality wool textiles for high-end garments. The factory combines traditional craftsmanship with modern technology, employing advanced spinning and weaving equipment to process fine wool fibers into luxurious suiting materials. The facility features specialized combing machines that align long wool fibers parallel to each other, creating the characteristic smooth finish of worsted wool. State-of-the-art quality control systems monitor every stage of production, from raw wool selection to final fabric finishing. The factory utilizes precision dyeing technology to ensure color consistency and implements eco-friendly processing methods to minimize environmental impact. Climate-controlled manufacturing spaces maintain optimal conditions for wool processing, while automated handling systems ensure efficient material flow throughout the production line. The facility's testing laboratory conducts rigorous assessments of fabric strength, durability, and finish quality, guaranteeing that each batch meets international standards. With a focus on sustainability, the factory incorporates water recycling systems and energy-efficient machinery, making it a leader in responsible textile manufacturing.