pabrik tekstil wol merino alami

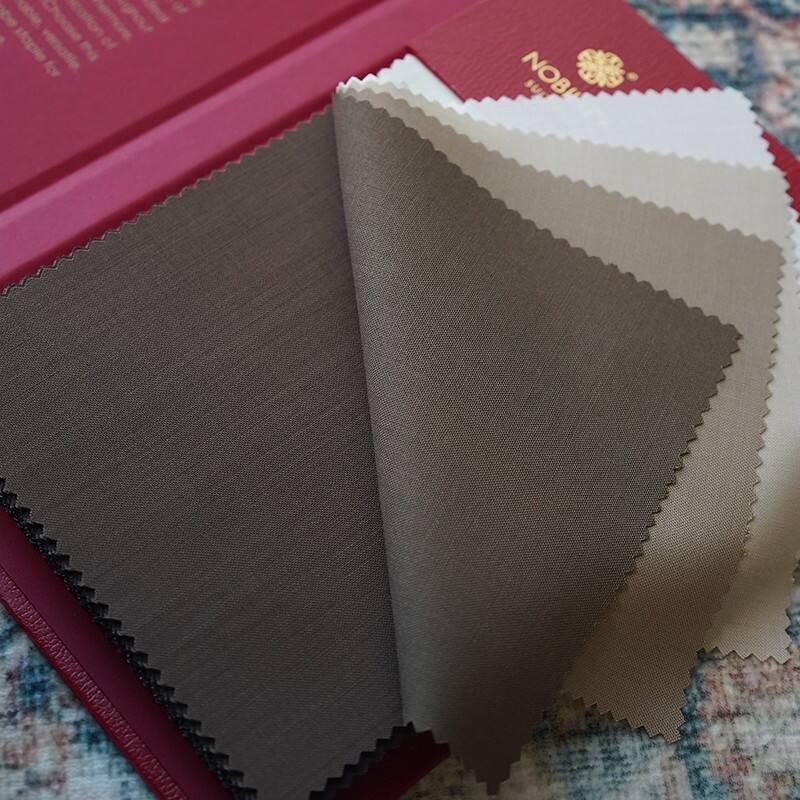

Sebuah pabrik tekstil wol merino alami merupakan fasilitas manufaktur mutakhir yang didedikasikan untuk mengubah wol merino premium menjadi tekstil berkualitas tinggi. Fasilitas ini menggunakan teknologi pemintalan canggih, sistem tenun otomatis, serta pengendalian kualitas presisi untuk memastikan keunggulan produk yang konsisten. Fungsi utama pabrik meliputi sortasi dan penggradasian wol, pencucian dan pembersihan, proses penyerat dan penyisiran, pemintalan benang, penenunan kain, serta perlakuan akhir. Sistem sensor modern memantau setiap tahap produksi, menjaga suhu dan kelembapan optimal yang penting dalam pengolahan wol. Fasilitas ini menerapkan praktik berkelanjutan, termasuk sistem daur ulang air dan mesin hemat energi, sehingga mengurangi dampak lingkungan sekaligus memaksimalkan efisiensi produksi. Laboratorium pengujian canggih di dalam pabrik memastikan semua produk memenuhi standar kualitas dan spesifikasi internasional. Kemampuan pabrik mencakup produksi berbagai bobot dan jenis tekstil, mulai dari wol merino ultra halus yang cocok untuk pakaian mewah hingga kain yang lebih kuat untuk pakaian luar ruangan. Sistem desain berbantuan komputer memungkinkan pembuatan pola yang presisi serta penyesuaian produk sesuai spesifikasi pelanggan. Fasilitas ini juga menerapkan sistem ketertelusuran yang ketat, mendokumentasikan perjalanan wol dari sumber hingga produk akhir, guna menjamin transparansi dan jaminan kualitas di seluruh rantai pasok.