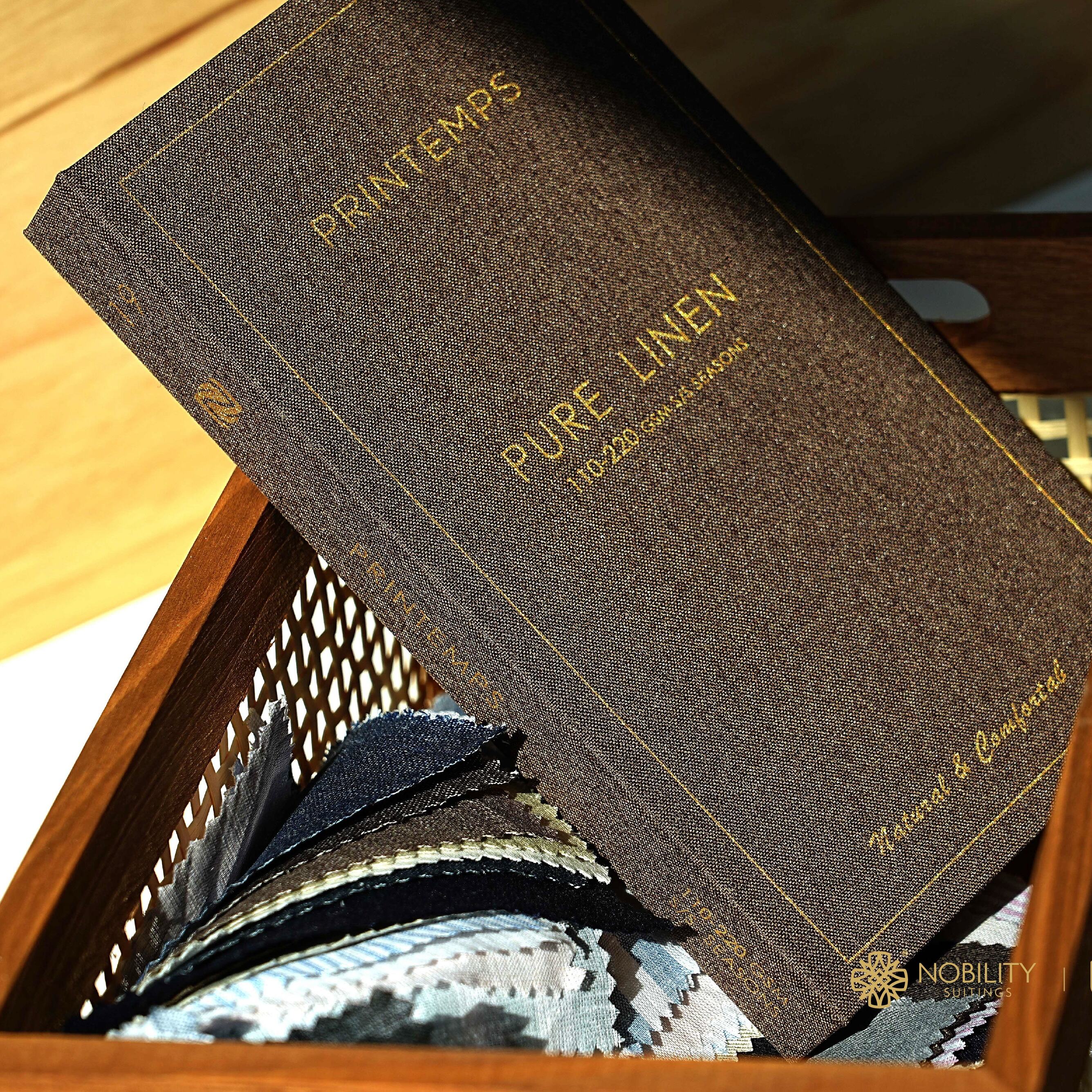

유기농 순수 린넨 원단 공장

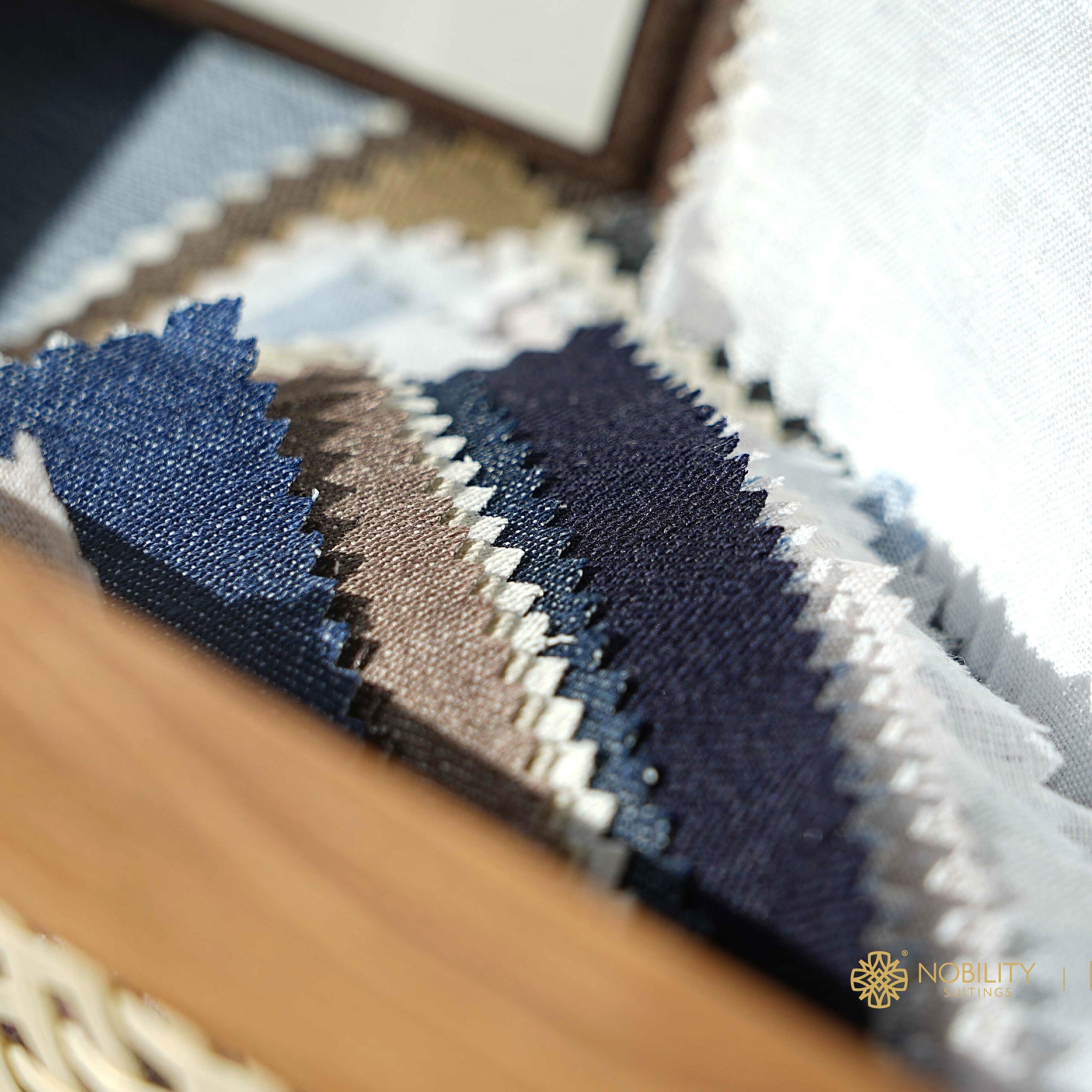

유기농 순수 리넨 원단 공장은 지속 가능한 섬유 제조의 정점을 상징하며, 전통 장인 정신과 현대 기술을 결합하여 최고 품질의 리넨 원단을 생산합니다. 최첨단 시설을 갖춘 이 공장은 원사에서 완제품까지 유기농 아마의 전 공정을 전문으로 하며, 생산 과정 전반에 걸쳐 엄격한 환경 기준을 준수합니다. 공장은 온도 조절이 가능한 공정 구역과 습도 조절이 가능한 보관 시설을 갖춘 첨단 방적 및 제직 장비를 사용하여 최적의 원단 품질을 보장합니다. 특히, 최고 수준의 원단 가공 기준을 유지하면서 환경 영향을 최소화하는 폐쇄형 순환 정수 시스템을 갖추고 있습니다. 최첨단 자동화 시스템을 도입하여 일관된 품질 관리를 실현하는 동시에, 원단의 고유한 특성을 유지하는 리넨 제조의 장인 정신을 그대로 보존하고 있습니다. 공장 내 품질 보증 실험실에서는 섬유 강도, 색상 견뢰도, 내구성에 대한 엄격한 테스트를 실시하여 모든 배치가 국제 기준을 충족하는지 확인합니다. 공장의 유기농 인증 노력은 공급망 전반에 걸쳐 적용되며, 아마 재배지에서 완제품에 이르기까지 완벽한 추적이 가능합니다. 이러한 포괄적인 접근 방식을 통해 환경적으로 책임감 있을 뿐만 아니라 전 세계 고급 섬유 시장의 엄격한 기준을 충족하는 프리미엄 리넨 원단이 탄생했습니다.