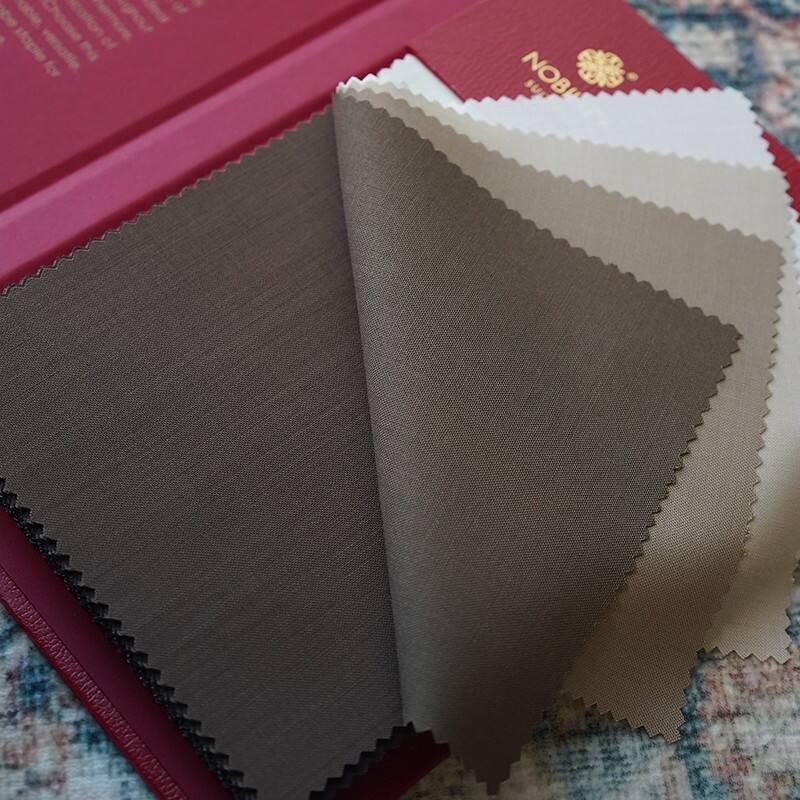

oem-leverandør av stoff i ren ull

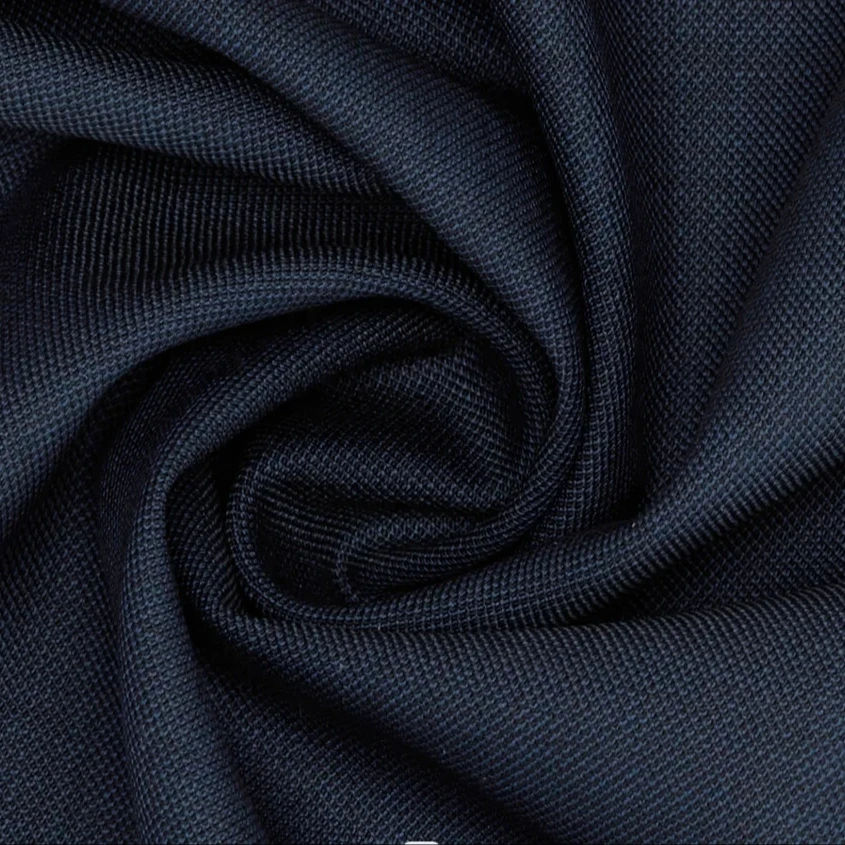

En OEM-leverandør av rene ullstoff representerer en avgjørende lenke i tekstilindustriens verdiskapningskjede, og spesialiserer seg på produksjon og tilpasning av høykvalitets ullstoff etter kundens spesifikasjoner. Disse leverandørene kombinerer tradisjonell håndverk med moderne produksjonsteknikker for å lage premium ulltekstiler som oppfyller mangfoldige markedskrav. De benytter avansert spinn- og vevemaskineri og implementerer strenge kvalitetskontrolltiltak gjennom hele produksjonsprosessen, fra råullutvelgelse til ferdig stoffbehandling. Leverandørens ekspertise omfatter ulike typer ullstoff, inkludert worsted, woolen og spesialblandinger, hver produsert etter bestemte krav til vekt, struktur og ytelse. Deres produksjonskapasitet omfatter vanligvis hele spekteret av produksjonsprosesser, inkludert ullsortering, vasking, karding, spinning, veving og overflatebehandlinger. Moderne OEM-leverandører av rene ullstoff integrerer også bærekraftige praksiser for å sikre miljømessig overholdelse samtidig som de opprettholder produktkvalitet. De tilbyr omfattende testtjenester for stoffegenskaper som strekkfasthet, pillingmotstand og fargelysthet, og garanterer at hver parti oppfyller internasjonale standarder og kundens spesifikasjoner.