fashion brand wool fabric sourcing own factory

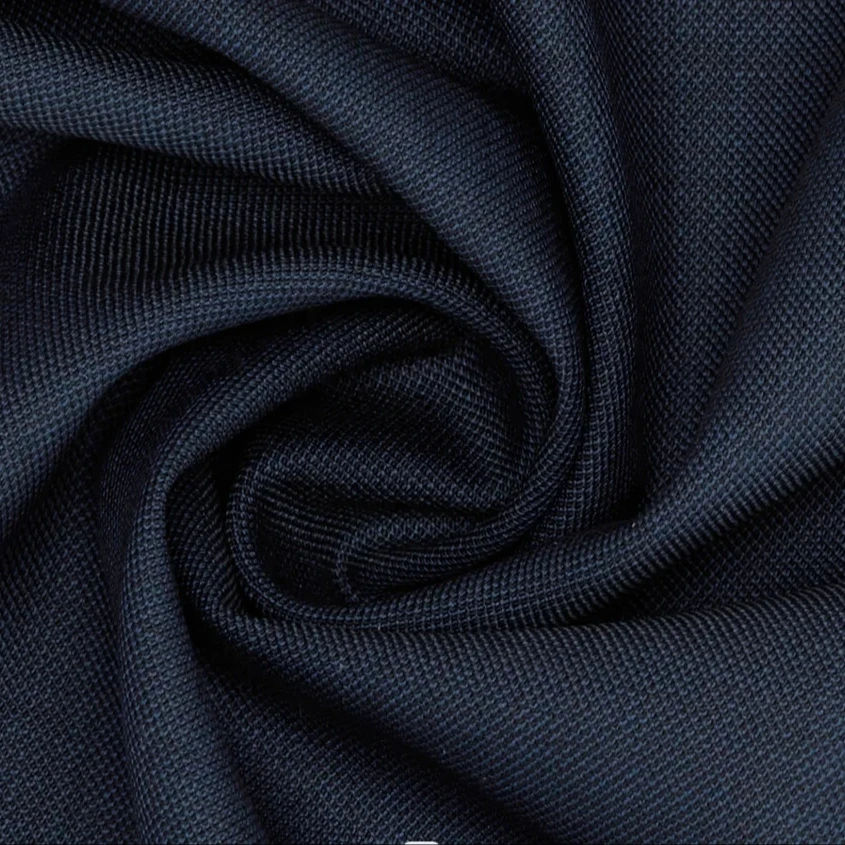

A fashion brand wool fabric sourcing own factory represents a vertically integrated manufacturing facility that specializes in producing high-quality wool textiles for fashion applications. These facilities combine traditional craftsmanship with modern manufacturing technologies to create premium wool fabrics. The factory encompasses multiple production stages, from raw wool processing to finished fabric creation, ensuring complete control over quality and consistency. State-of-the-art machinery handles various processes including wool sorting, scouring, carding, spinning, weaving, and finishing treatments. Advanced quality control systems monitor each production phase, maintaining strict standards for fiber quality, yarn uniformity, and fabric performance. The facility typically features specialized departments for fabric design, testing laboratories for quality assurance, and research and development units for innovative textile solutions. Environmental control systems regulate temperature and humidity levels to optimize wool processing conditions. Modern dyeing and finishing equipment enables precise color matching and special fabric treatments. The factory's integrated approach allows for customization of fabric specifications, including weight, texture, and performance characteristics, meeting diverse fashion industry requirements. This comprehensive manufacturing setup ensures traceability, sustainability, and efficient production timelines while maintaining consistent quality standards throughout the process.