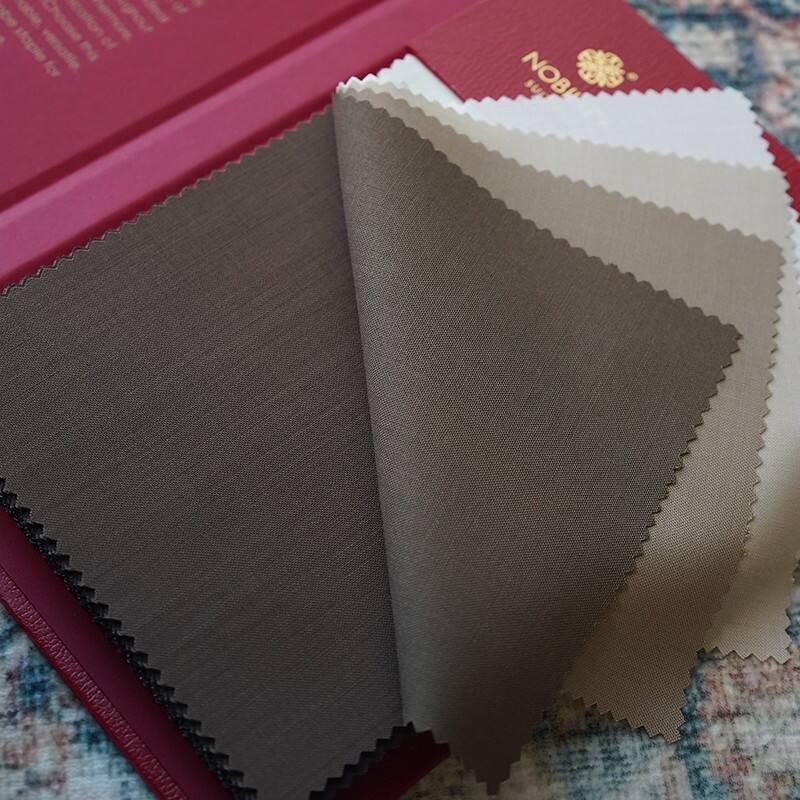

oem wool fabric supplier with own factory

An OEM wool fabric supplier with its own factory represents a comprehensive manufacturing solution in the textile industry, offering end-to-end production capabilities for high-quality wool fabrics. These facilities typically encompass state-of-the-art machinery for wool processing, spinning, weaving, and finishing processes. The integration of modern technology allows for precise quality control at every production stage, ensuring consistent fabric characteristics and superior finish. Such suppliers maintain dedicated research and development departments to create innovative wool blends and treatments, meeting diverse customer specifications and market demands. The in-house production capability enables direct control over raw material sourcing, processing techniques, and quality assurance protocols. These facilities often utilize advanced testing equipment to verify fabric properties such as tensile strength, color fastness, and wear resistance. With comprehensive manufacturing capabilities, these suppliers can handle various wool types, from fine merino to robust sheep's wool, producing fabrics suitable for fashion, upholstery, and technical applications. The factory setup typically includes specialized sections for eco-friendly treatments and sustainable production methods, aligning with global environmental standards.