pure wool fabric manufacturer with own factory

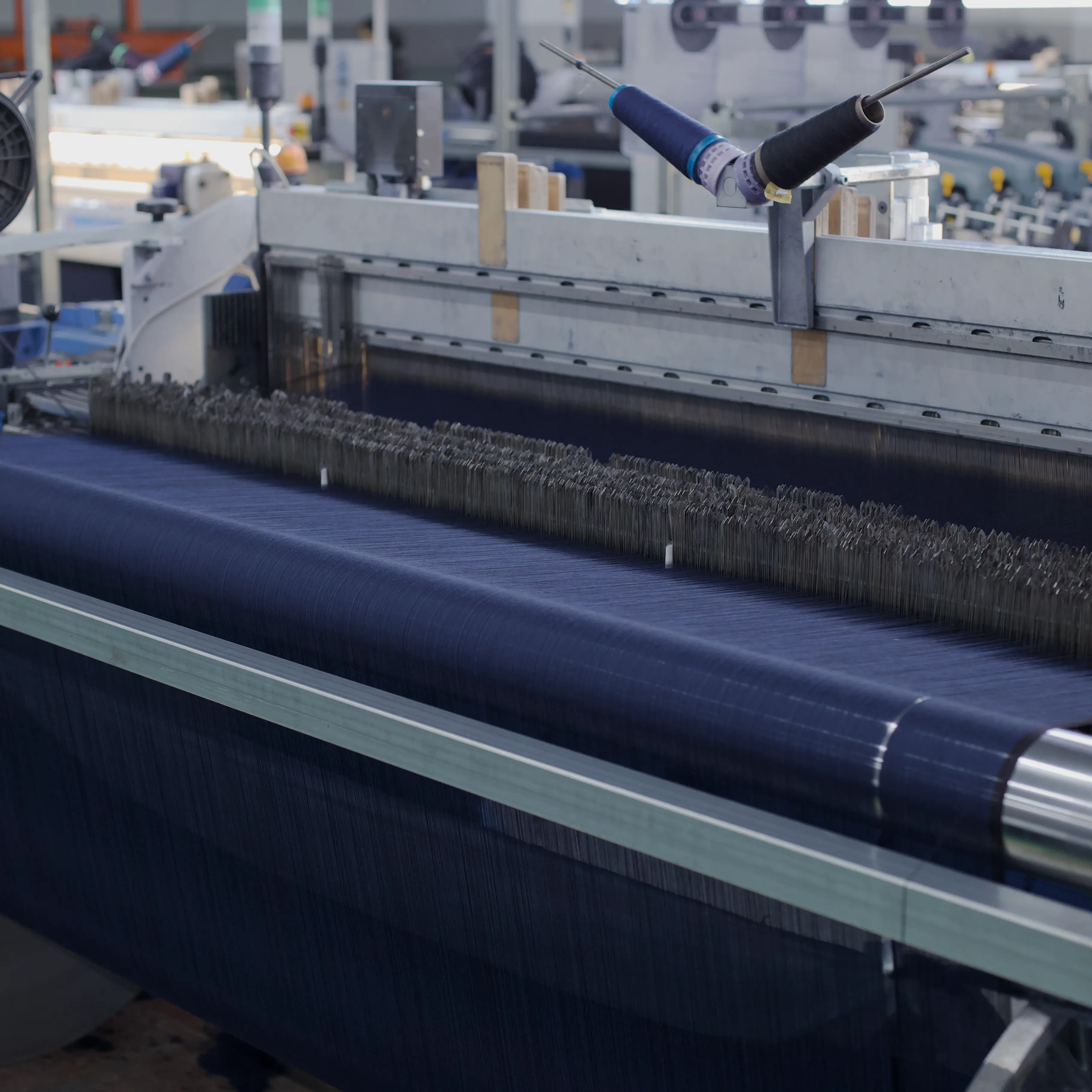

A pure wool fabric manufacturer with its own factory represents a comprehensive solution in textile production, combining traditional craftsmanship with modern manufacturing capabilities. These facilities maintain complete control over the production process, from raw wool selection to finished fabric delivery. The manufacturing facility typically encompasses multiple specialized departments, including wool sorting, scouring, carding, spinning, weaving, and finishing operations. Advanced quality control systems monitor each production phase, ensuring consistent fabric quality and performance. State-of-the-art machinery, including computerized looms and precision testing equipment, enables the production of various wool fabric types, from fine merino suits to robust outerwear materials. The facility's vertical integration allows for customized production runs, specific fabric specifications, and innovative textile developments. Environmental control systems maintain optimal temperature and humidity levels throughout the production area, essential for wool fiber processing. The manufacturer's in-house capabilities extend to specialized treatments such as anti-pilling, water-resistance, and moth-proofing, all performed under strict quality guidelines. This comprehensive approach ensures complete traceability of materials and processes, meeting international standards and certification requirements.