own factory wool fabric

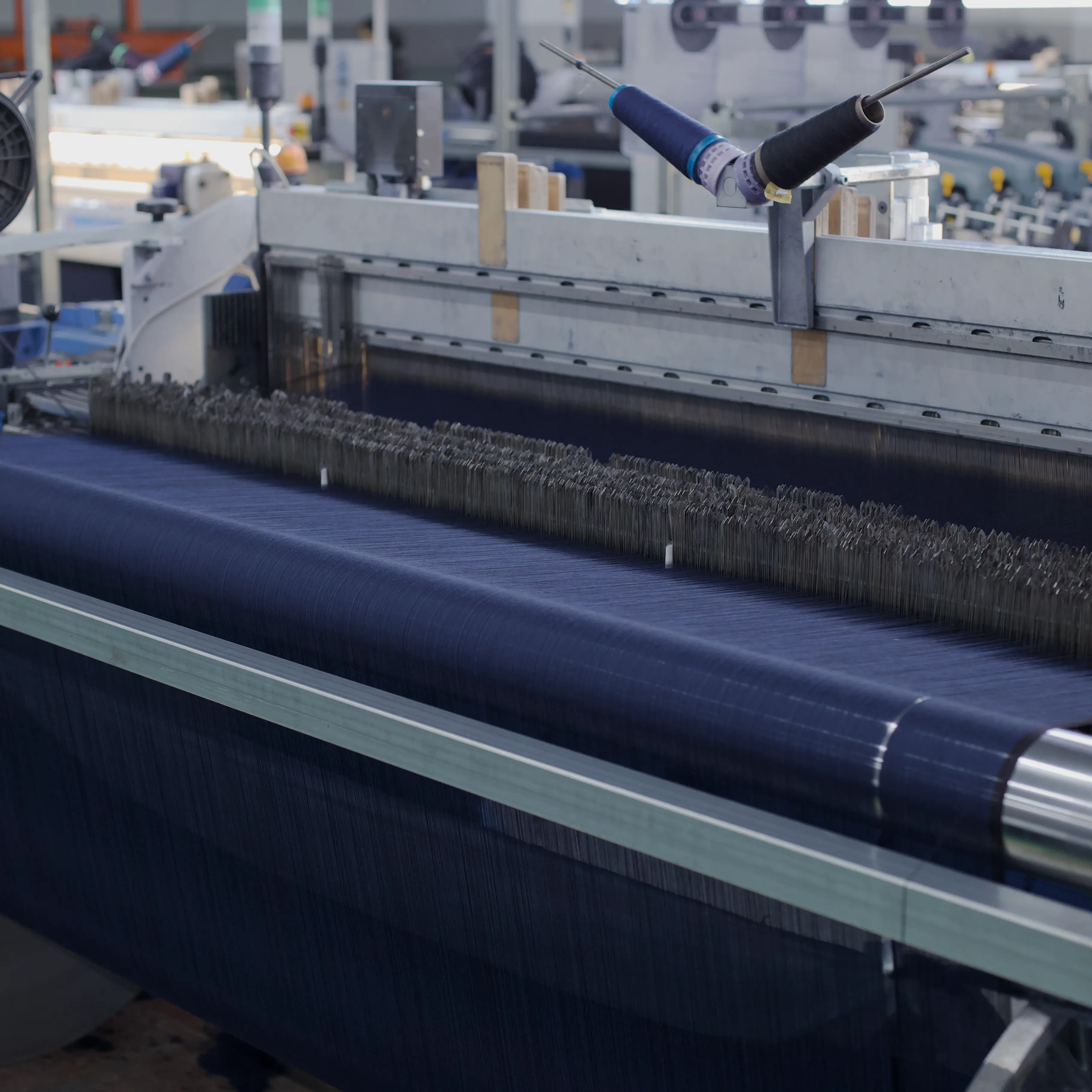

Own factory wool fabric represents a premium textile solution that combines traditional craftsmanship with modern manufacturing excellence. This versatile material is produced in dedicated facilities where every step of the production process is meticulously controlled, from raw wool selection to final finishing. The fabric undergoes rigorous quality control measures, ensuring consistent texture, durability, and performance across all batches. Through advanced weaving techniques and state-of-the-art machinery, these facilities create wool fabrics that maintain superior thermal regulation properties while offering exceptional comfort and breathability. The production process incorporates innovative treatments that enhance the fabric's natural characteristics, including wrinkle resistance, moisture-wicking capabilities, and color fastness. Own factory wool fabric is particularly valued in high-end fashion, professional attire, and luxury home textiles, where quality and consistency are paramount. The controlled manufacturing environment allows for customization of weight, texture, and finish, making it suitable for various applications from lightweight summer suits to heavy winter coats.