wool fabric supplier with own factory

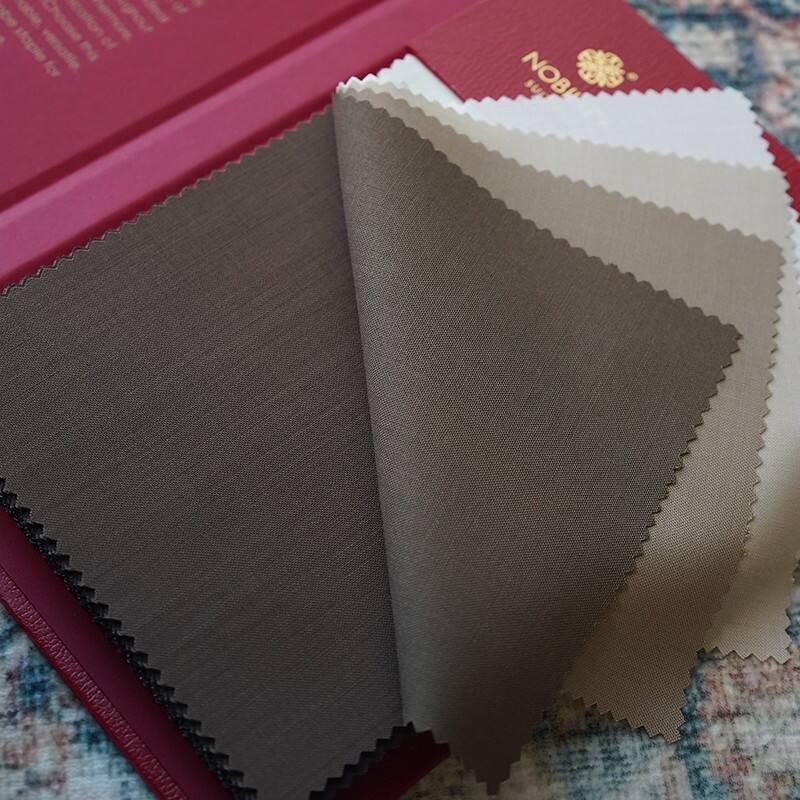

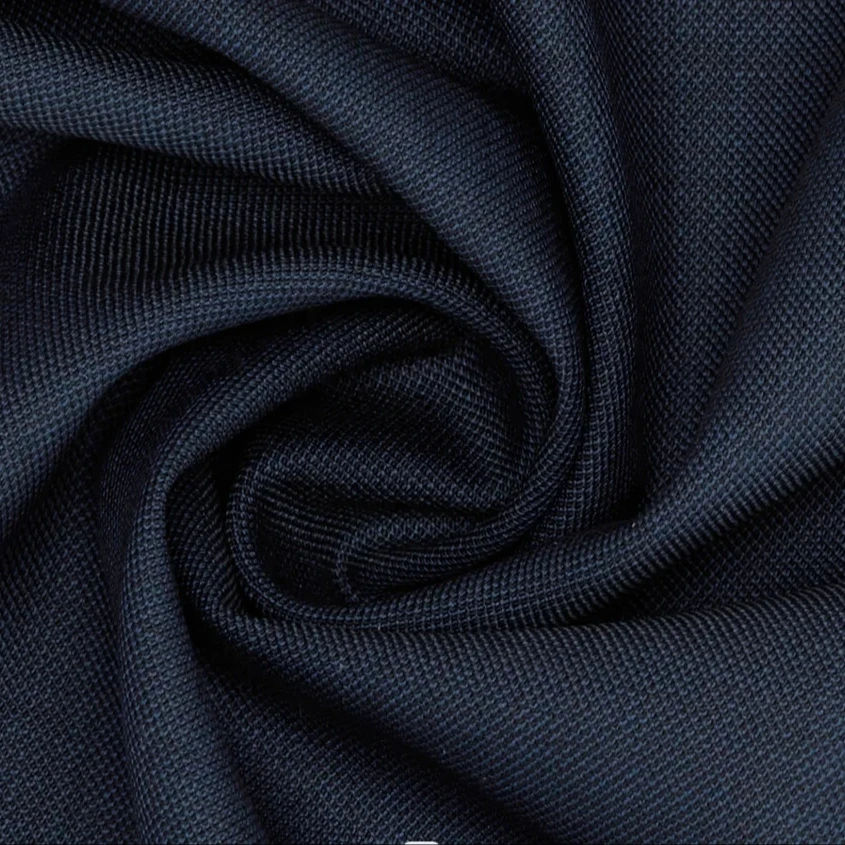

A wool fabric supplier with its own factory represents a comprehensive solution in the textile industry, offering end-to-end production capabilities and quality control. These facilities combine traditional wool processing expertise with modern manufacturing technologies to deliver superior wool fabrics. The integrated factory setup includes state-of-the-art machinery for wool sorting, cleaning, carding, spinning, weaving, and finishing processes. Quality control measures are implemented at every stage, from raw material selection to final product inspection. The factory's capabilities typically include producing various wool fabric types, from fine merino wool to robust tweed materials, with customizable weights, patterns, and finishes. Advanced testing laboratories ensure fabric performance meets international standards for durability, colorfastness, and wear resistance. The facility's vertical integration allows for better cost management, shorter production timelines, and consistent quality maintenance. Environmental considerations are often incorporated through sustainable practices, water recycling systems, and energy-efficient equipment. With direct control over the manufacturing process, these suppliers can offer customized solutions, flexible production volumes, and reliable delivery schedules to meet diverse client requirements.