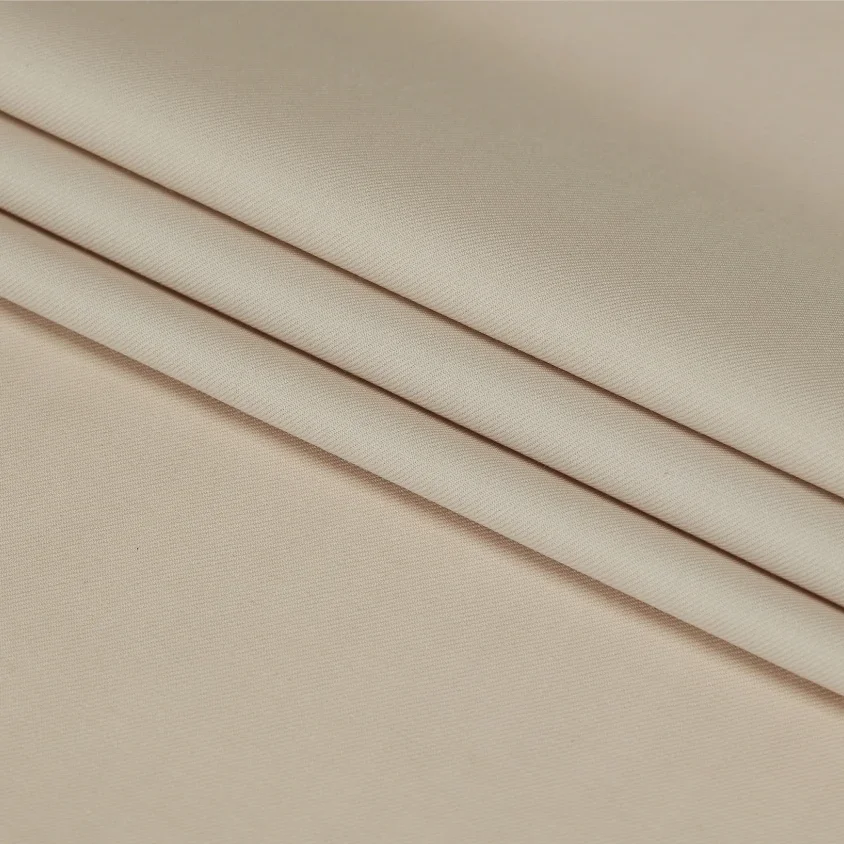

organic wool fabric producer own factory

The organic wool fabric producer's own factory represents a state-of-the-art manufacturing facility dedicated to creating premium quality wool textiles through sustainable practices. This vertically integrated facility manages the entire production process, from raw wool processing to finished fabric creation. The factory encompasses modern spinning equipment, advanced weaving machinery, and specialized finishing departments that ensure consistent quality control throughout production. The facility features environmentally conscious processing units that minimize water usage and employ eco-friendly cleaning agents. With automated climate control systems maintaining optimal temperature and humidity levels, the factory ensures ideal conditions for wool processing. The production line incorporates cutting-edge technology for wool grading, scouring, carding, and spinning, resulting in superior yarn quality. The weaving department utilizes computerized looms that can produce various fabric weights and patterns while maintaining precise tension control. Quality assurance laboratories equipped with advanced testing equipment monitor fabric properties, ensuring compliance with international standards. The factory's dyeing and finishing department employs water-efficient technologies and natural dyes, maintaining environmental sustainability while achieving superior color fastness and fabric handle. This comprehensive facility serves various market segments, from fashion and apparel to home textiles and technical applications, offering customizable solutions for different customer requirements.