group order for wool apparel production

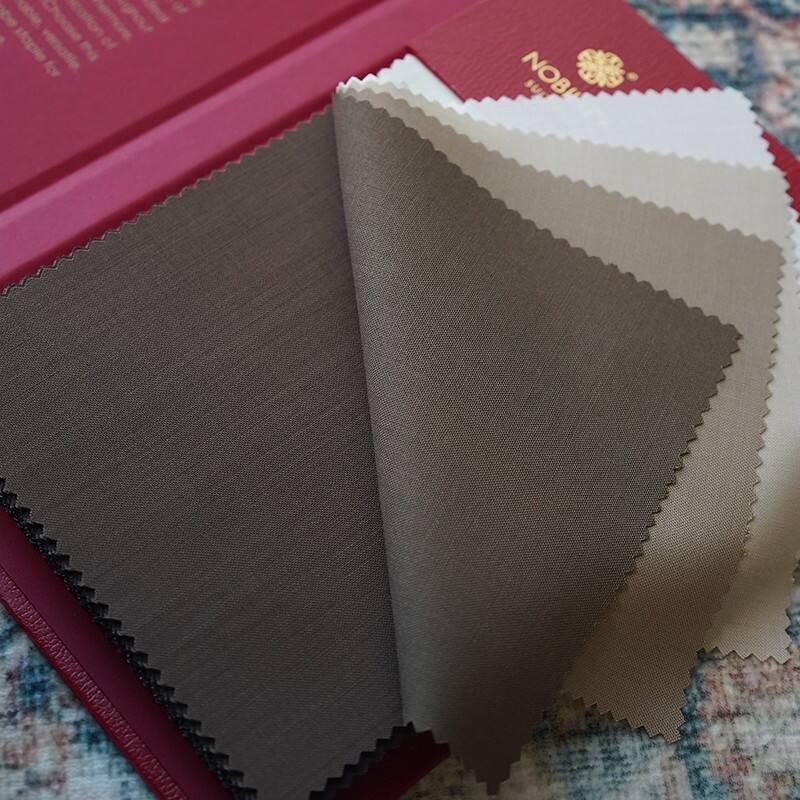

Group order for wool apparel production represents a strategic approach to manufacturing that combines efficiency, cost-effectiveness, and quality assurance. This production method enables multiple buyers to consolidate their wool apparel requirements into a single, coordinated manufacturing order. The process typically begins with detailed specifications gathering from all participating parties, followed by material sourcing, production planning, and quality control implementation. Advanced technological features include digital production tracking systems, automated quality inspection points, and real-time progress monitoring capabilities. The system accommodates various wool types and garment specifications while maintaining consistent quality standards across the entire batch. Applications span across seasonal collections, corporate uniforms, and specialized wool garment productions. The technology integrates modern ERP systems with traditional wool processing expertise, ensuring optimal resource allocation and production scheduling. This approach particularly benefits businesses seeking economies of scale without compromising on quality or customization options. The system's flexibility allows for various production volumes while maintaining cost efficiency through shared resources and streamlined logistics.