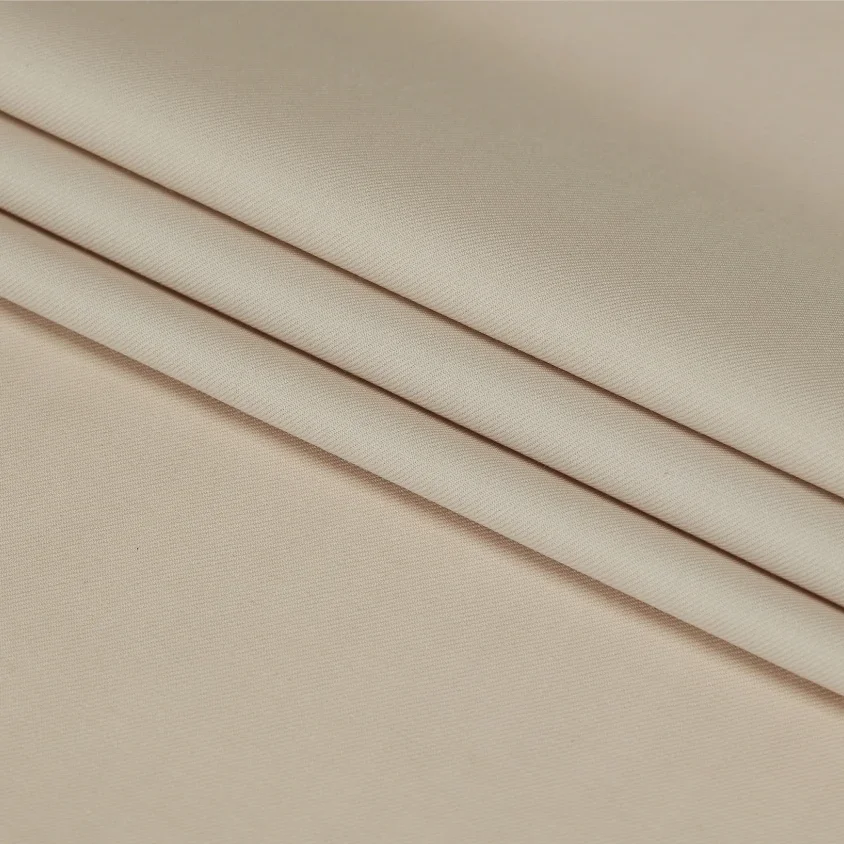

oem wool fabric group order

OEM wool fabric group orders represent a sophisticated approach to textile procurement, combining cost efficiency with quality assurance. This procurement method enables businesses to source premium wool fabrics directly from manufacturers while maintaining specific quality standards and customization options. The process typically involves bulk ordering of wool fabrics manufactured according to precise specifications, including fiber composition, weight, texture, and finishing treatments. These group orders leverage economies of scale, allowing participants to access higher quality materials at more competitive prices. The technological features include advanced quality control systems, standardized testing procedures, and consistent color matching across production batches. The fabrics undergo rigorous testing for durability, colorfastness, and wear resistance, ensuring they meet international standards. Applications span across various sectors, including high-end fashion, corporate uniforms, home textiles, and specialized industrial uses. The service typically includes comprehensive quality inspection, customized packaging solutions, and flexible minimum order quantities to accommodate different business scales. This approach also incorporates sustainable practices in wool processing and manufacturing, addressing growing environmental concerns in the textile industry.