The textile industry has witnessed remarkable evolution over the centuries, yet pure wool remains one of the most sought-after natural fibers for wholesale buyers and professional tailors worldwide. This premium material offers unmatched versatility, durability, and comfort that synthetic alternatives simply cannot replicate. Understanding the comprehensive benefits of pure wool enables businesses to make informed decisions when sourcing materials for high-quality garments and textile products.

Superior Performance Characteristics of Natural Wool Fibers

Exceptional Thermal Regulation Properties

Pure wool demonstrates remarkable thermal regulation capabilities that make it invaluable for creating garments suitable for diverse climatic conditions. The natural crimp structure of wool fibers creates millions of tiny air pockets that provide excellent insulation while allowing moisture vapor to escape. This unique property enables wool garments to keep wearers warm in cold environments while preventing overheating in moderate temperatures.

Professional tailors appreciate how pure wool maintains its insulating properties even when slightly damp, unlike synthetic materials that lose effectiveness when exposed to moisture. The fiber's ability to absorb up to thirty percent of its weight in moisture without feeling wet makes it ideal for creating comfortable, breathable garments that perform exceptionally across various weather conditions.

Natural Moisture Management System

The hygroscopic nature of pure wool creates an advanced moisture management system that surpasses most synthetic alternatives. Wool fibers naturally wick moisture away from the skin and release it into the atmosphere through evaporation. This process helps maintain optimal body temperature and reduces the uncomfortable feeling of dampness that often occurs with synthetic fabrics.

Wholesale buyers recognize that garments made from pure wool require less frequent washing due to the fiber's natural antibacterial properties and odor resistance. The lanolin content in wool provides inherent antimicrobial benefits, making it an excellent choice for creating long-lasting, hygienic clothing items that maintain freshness between washes.

Economic Advantages for Wholesale and Manufacturing Operations

Long-term Cost Effectiveness

While the initial investment in pure wool may be higher than synthetic alternatives, the long-term economic benefits significantly outweigh the upfront costs. Wool garments typically last decades with proper care, providing exceptional value for both manufacturers and end consumers. The durability of wool fibers means less frequent replacement needs, reducing overall material costs over time.

Tailoring businesses benefit from wool's workability and forgiving nature during the construction process. The fiber's natural elasticity allows for easier fitting adjustments and alterations, reducing waste and improving overall production efficiency. This flexibility translates to higher profit margins and increased customer satisfaction rates.

Market Demand and Premium Positioning

Consumer awareness of sustainable and natural materials continues to drive strong market demand for pure wool products. Wholesale buyers can position wool garments in premium market segments, commanding higher prices and better profit margins compared to synthetic alternatives. The luxury perception associated with natural wool creates opportunities for brand differentiation and customer loyalty.

International fashion trends consistently favor natural materials, making pure wool a reliable choice for forward-thinking wholesalers and manufacturers. The timeless appeal of wool ensures stable demand across diverse geographic markets and demographic segments, providing business stability and growth opportunities.

Technical Processing and Manufacturing Benefits

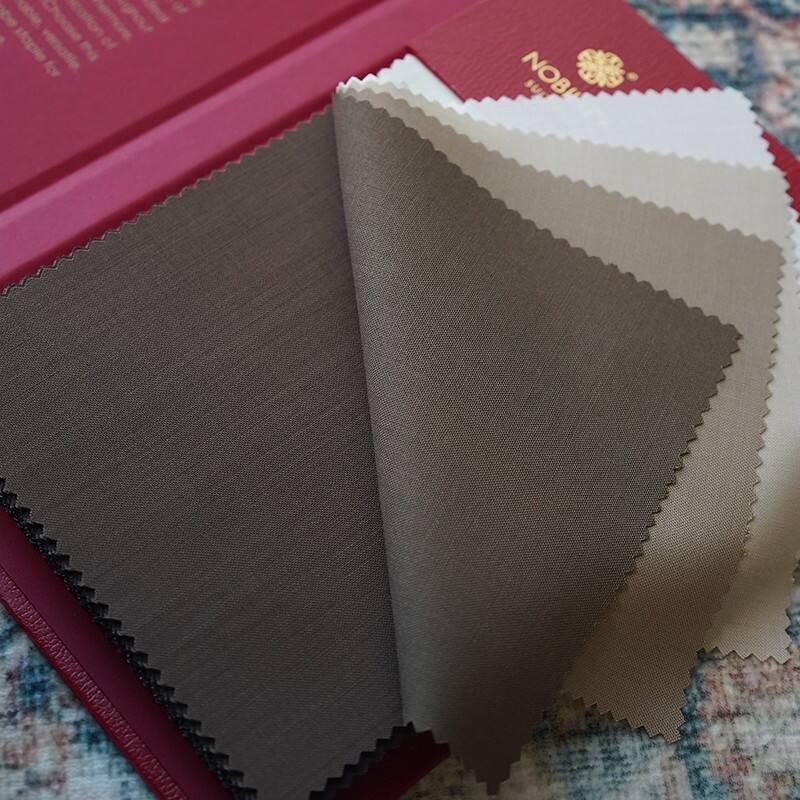

Versatile Dyeing and Finishing Options

Pure wool accepts dyes exceptionally well, allowing for vibrant, long-lasting colors that resist fading over time. The protein structure of wool fibers creates strong chemical bonds with various dye types, resulting in superior color fastness compared to many synthetic materials. This characteristic enables manufacturers to create rich, consistent colors that maintain their appearance through multiple wear and wash cycles.

The natural elasticity and resilience of pure wool facilitate various finishing processes, including pressing, steaming, and shaping procedures that are essential in professional tailoring. Wool's ability to hold creases and maintain shape makes it ideal for creating structured garments that retain their intended silhouette over extended periods.

Compatibility with Advanced Manufacturing Techniques

Modern textile manufacturing equipment works exceptionally well with pure wool, allowing for efficient processing while maintaining fiber integrity. The natural properties of wool complement both traditional hand-tailoring techniques and contemporary automated production methods. This versatility enables manufacturers to scale operations while preserving the quality characteristics that make wool desirable.

Quality control processes are simplified when working with pure wool due to the fiber's consistent performance characteristics and predictable behavior during processing. This reliability reduces production variables and helps maintain uniform quality standards across large manufacturing runs.

Environmental and Sustainability Considerations

Renewable Resource and Biodegradability

Pure wool represents one of the most sustainable fiber choices available to the textile industry. As a renewable resource that regenerates annually through natural sheep growth cycles, wool provides an environmentally responsible alternative to petroleum-based synthetic fibers. The biodegradable nature of wool ensures that end-of-life garments do not contribute to long-term environmental pollution.

Sustainable sourcing practices in the wool industry continue to improve, with many suppliers implementing ethical animal welfare standards and environmentally conscious farming methods. Wholesale buyers can leverage these sustainability credentials to meet growing consumer demands for environmentally responsible products while supporting ethical supply chain practices.

Carbon Footprint and Energy Efficiency

The processing of pure wool typically requires less energy-intensive manufacturing procedures compared to synthetic fiber production. Natural wool processing relies primarily on mechanical methods and lower-temperature treatments, resulting in reduced carbon emissions throughout the production cycle. This energy efficiency contributes to lower overall environmental impact and supports corporate sustainability initiatives.

Transportation and storage of pure wool products often prove more efficient due to the fiber's natural compression capabilities and resistance to damage during handling. These logistical advantages reduce shipping costs and minimize packaging requirements, further enhancing the environmental benefits of choosing wool over synthetic alternatives.

Quality Control and Performance Standards

Consistent Fiber Quality and Grading Systems

The wool industry has developed sophisticated grading and classification systems that ensure consistent quality standards across different suppliers and regions. These standardized approaches enable wholesale buyers to specify exact quality requirements and receive reliable, predictable materials for their manufacturing needs. The established grading criteria cover fiber diameter, length, strength, and purity levels.

Professional testing methods for pure wool provide accurate assessments of material properties before production begins. These quality assurance processes help prevent costly manufacturing problems and ensure that finished products meet performance expectations. The transparency of wool quality standards facilitates informed purchasing decisions and supplier relationships.

Traceability and Source Verification

Modern pure wool supply chains offer excellent traceability capabilities, allowing buyers to verify the origin and processing history of their materials. This transparency supports quality control initiatives and enables businesses to make informed decisions about supplier relationships. Traceability also facilitates compliance with various industry standards and certifications.

Documentation and certification processes for pure wool provide reliable verification of material authenticity and quality characteristics. These systems help prevent counterfeit materials and ensure that buyers receive genuine pure wool products that meet their specifications and performance requirements.

FAQ

How does pure wool compare to synthetic alternatives in terms of durability

Pure wool significantly outperforms most synthetic alternatives in terms of long-term durability and wear resistance. While synthetic fibers may initially appear strong, they tend to degrade more rapidly under normal use conditions, developing pilling, losing shape, and becoming brittle over time. Pure wool maintains its structural integrity for decades with proper care, making it more cost-effective despite higher initial investment costs.

What care requirements should be considered when working with pure wool

Pure wool requires specific care protocols to maintain its properties and appearance, but these requirements are generally straightforward and well-established. Most pure wool products benefit from professional cleaning or gentle hand washing with wool-specific detergents. Proper storage in breathable environments and protection from moths are essential considerations. However, the natural odor resistance and soil-repelling properties of wool mean that frequent cleaning is often unnecessary.

Can pure wool be effectively used in modern automated manufacturing processes

Yes, pure wool adapts exceptionally well to modern manufacturing technologies and automated production systems. Contemporary textile machinery is specifically designed to handle natural fibers like wool while preserving their beneficial properties. The key is maintaining appropriate processing conditions, including temperature control and gentle handling procedures. Many manufacturers successfully combine automated efficiency with wool's natural performance characteristics.

What factors should wholesale buyers consider when sourcing pure wool

Wholesale buyers should evaluate several critical factors when sourcing pure wool, including fiber grade, supplier certifications, traceability documentation, and consistency of supply. Price considerations should account for long-term value rather than just initial costs. Establishing relationships with reputable suppliers who provide quality guarantees and technical support is essential for successful pure wool procurement strategies.